PRODUCTS

The Tarco motiv® Product Line

Our motiv® control products incorporate over 150 years of cumulative engineering experience in programming, design, and operation. We believe there are no better control systems in the marketplace. All motiv® systems are completely configurable from an operator interface. This makes them user-friendly as well as easy to maintain and troubleshoot. Based on a fully open architecture, motiv® control system software is kept current through constant innovation and can be implemented on all common programmable control hardware platforms.

motiv® TCS – Turbine Control System

Tarco’s motiv® Turbine Control Systems (motiv® TCS) are fully engineered, PLC-based upgrades for gas and steam turbines. These upgrades improve reliability, increase maintainability and enhance the operation of older gas turbines, extending the useful life of the equipment and minimizing downtime losses.

motiv® TCS Turbine Control Systems can be configured for package control and fuel control of gas turbine driven gas compressors, generators, and pumps, and can also include water injection control, or steam injection control.

motiv® TCS systems are available with the following functions:

- Alarm and shutdown

- Surge control

- Fuel control (governor)

- Start sequencing

- Auxiliary system control

- Valve sequencing

- Process valve control

- Engine/compressor/generator diagnostics

- Vibration monitoring

- End device diagnostics

motiv® TCS is an open architecture design. It is completely expandable and ideal for new installations or control system upgrades.

- Turbine-Compressor

- Turbine-Pump

- Turbine-Generator

motiv® RCS – Reciprocating Engine Control System

Tarco’s motiv® Reciprocating Control Systems (motiv® RCS) provide cost-effective control retrofits for reciprocating engine and electric motor packages. The PLC-based system is available with the following functions:

- Speed control (governor)

- Torque control

- Air/fuel ratio control

- Ignition timing set point generation

- Temperature controllers

- Capacity control

- DCS/SCADA interface, and a graphics operator interface for system status

- Trending and data logging

motiv® FCS – Fuel Control Systems

Some clients only need to upgrade their existing fuel control or governor and do not require full package control. To address their needs, Tarco developed the motiv® FCS. This is virtually a “plug and play” retrofit solution.

The motiv® FCS is a cable for cable, point for point replacement unit designed to quickly and affordably retrofit existing analog or obsolete digital controls. Tarco’s motiv® Fuel Control Systems (motiv® FCS) have been installed worldwide, and have proven to be an excellent, reliable solution, especially where budgets are limited.

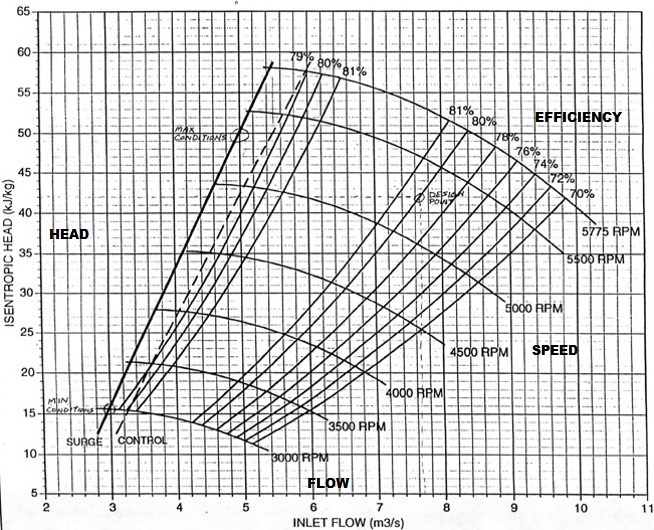

motiv® ACS – Anti-Surge Control Systems

Tarco’s motiv® ACS serves as a package comprised of a tight integration of anti-surge control, compressor control, and process control functions into a single package, where separate controllers are not required for each key function. This feature eliminates complicated and troublesome communication, increases reliability and decreases cost.

Tarco offers advanced anti-surge control solutions to OEMs and end-users that provide significant cost savings, when compared to traditional ‘black-box’ approaches. We have developed a group of code-sets that can be hosted in many different control systems. The flexibility of controller platforms means a lower cost of ownership by integrating compressor solutions into the user’s preferred PLC controller and DCS system.

Benefits of the motiv Anti-Surge Control Systems:

- Integrated control capability

- Open architecture system

- Non-proprietary interfaces

- Simplified interface to DCS or SCADA Features

- Single and multi-stage machines

- Integrated air/fuel ratio option

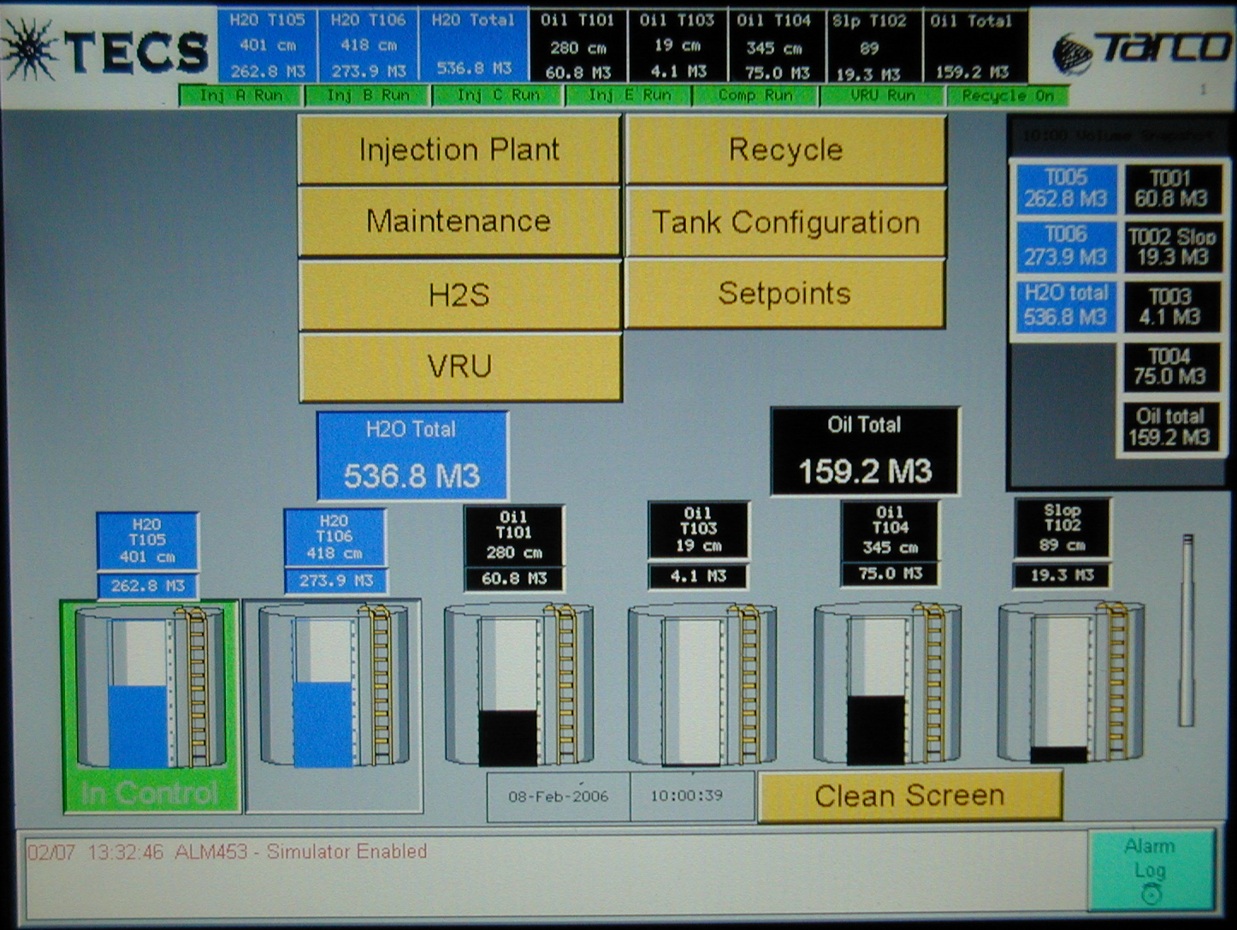

motiv® OBS – Oil Battery Control System

Tarco’s motiv® OBS (Oil Battery Control System) facilitates easy control of the entire facility. It includes wireless callout, injection pumps, tank level control, VRU control, recycle control, maintenance bypasses, set point management, alarm, and shutdowns, data capture and data logging.

The oil battery controller interface provides real-time data of battery tank levels and volume. The motiv® OBS injection control system facilitates the control of pump start/stop setpoint, pump and tank level status, enabling/disabling of individual pump control, control tank selection, gauge time, hour meters and start counters. Overall, OBS is a fully-functional oil and gas facility controller system with template drawings, design, and programming.

motiv® HVC – Industrial HVAC Control System

Tarco’s motiv® HVC control systems are designed with CSA Class 1 Div. 2 certification. HVAC Control Systems are designed to provide flexibility in protocol-based communication, versatility in building management systems, and with a highly adaptable configuration. Tarco’s Industrial HVAC Control Systems are used in the following:

- Air handling units

- Package air conditioners

- Temperature control valves

- Electric unit heaters

- Temperature control valves

- Ridge vent & fans

- Dampers

- Alarm and status information

- Email messaging

motiv® FX – API Flow Computer

Tarco’s motiv® FX introduces an entirely new way of managing LACT (Lease Automatic Custody Transfer) unit operations. The microprocessor-based controller has been specifically designed to perform flow calculations for one meter run with one or two meters. The design also supports pressure, temperature and BS&W compensation, while the totalized values and logging data are stored on a compact flash and are easily accessible for reporting and audit. In addition, the motiv® FX systems can monitor and control a LACT facility with the following equipment:

- Up to three tanks

- Charge pumps

- Main pumps

- Diverter valves

- Shutoff valves

- Samplers